Extreme Light Infrastructure Nuclear Physics (ELI-NP) project - Măgurele Research Center

It all started when I found on the e-licitatie.ro (SEAP) website the tender notice for the award of the SF for the construction of a nuclear research center. There was not going to be an auction, it was a form of choosing the winner by Competitive Dialogue in three rounds. The first round was to take place in 15 days...

I applied, read the specifications, very "thin", for me "unclear". The solution was to start studying quantum physics at a gallop. It is extremely interesting, it is science fiction sometimes or incomprehensible for a man who doesn't consider time as the 4th dimension - architect's deformation.

How, necum, I convinced them. There was a panel of 20 or so physicists struggling to understand the language of the architect, who in turn was trying to understand their language. It seems we understood each other.

During this "direct dialog" I presented a volumetric proposal for the buildings to be designed; according to the contract, I had 28 calendar days to hand in the project. Surprise surprise, after confirmation of the winner, a new theme is issued, completely different from the first one.... and yet the deadline was only 28 days.

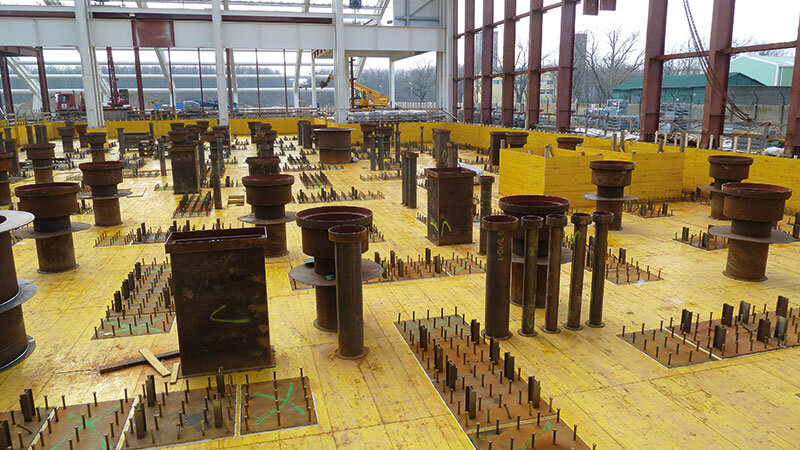

A research center consisting of a building in which two 10 PW (1015 W) lasers were being developed, another building in which a gamma particle accelerator plus experimental chambers and a building for laboratories necessary for the operation and preparation of the lasers and accelerator were being constructed. What was really a test within this theme: the protection of two of the buildings from micro-vibrations (technically the requirement was: ≤1 x 10-10 g2/Hz from 1 to 200 Hz, i.e. translated, an amplitude of maximum 0.1 microns), the accelerator building and the building containing the laser chamber. Also, the laser chamber, which must have a cleanliness class encountered only in microprocessor production, raised design and, more importantly, execution problems.

The activities described had to take place in a space with radiation protection walls, some of which were 2 m thick, with a concrete floor 1.5 m thick, the plan dimensions of two football pitches, and resting on two buildings of unequal mass, and therefore with different heights. And, as I said above, the whole assembly had to have a vibration amplitude of no more than 0.1 microns, no noise, a temperature of 20 ± 0.5 oC, etc.

The solution came from documentation. For radiation protection I went and asked questions at the G.S.I. Nuclear Research Center near Darmstadt, Germany, and at Rutherford in the UK, at the Nuclear Research Center near Oxford. At this stage of documentation, I was greatly helped by the people from the management of the beneficiary - the Institute of Physics and Nuclear Engineering "Horia Hulubei", in Măgurele.

I solved the vibration problem by researching known suppliers. We asked a large company in the USA and the answer was: look at our catalog and choose the product that meets your needs - impossible without a physicist specialized in micro-vibrations, and we couldn't find him in Romania; from France came the answer that they can execute anything according to a project that we produce, and from Germany came the answer that they can design and produce a system that fits within the parameters required by the theme.

For the clean rooms I consulted a Romanian technologist, with whom I had worked before, and so we established the conditions to be met and the materials to be used in the laser room and in some of the laboratories.

We drew up the project and after that, a tender was organized for the execution, launched on July 1, 2012, with completion in two months. A lot of questions were asked, some to the point and some strange or childish, from which I deduced that many builders did not understand what they had to do, in fact, they did not understand how complex the project was. They were taking it too lightly. The tender kept being postponed so that bidders could put together a compliant (coherent) bid, ending up taking 6 months to submit bids.

The winner was a European construction company with a representative office in Romania, in association with two others, one from Poland and one from Germany. And since then the "adventure" began...

Read the full text in issue 1 / 2015 of Arhitectura magazine

photo: Costel TUDORUȚ