Doubtful traditions workshop - Parametric design and digital 1:1 manufacturing methods

WORKSHOP QUESTIONABLE TRADITIONS - PARAMETRIC DESIGN AND 1:1 DIGITAL FABRICATION

| ARGUMENT The workshop has emerged as a response to the demand that exists in digital design and computational design respectively, taking into account the academic curriculum, where there is no such thing. From the very beginning we wanted to collaborate with foreign tutors in order to assist as many participants as possible. Thus, we invited with us (T_A_I, Tudor Cosmatu - STUDIO X, Prof. Christos Passas, DIA; Andrei Răducanu - Studio Neil Leach and Tobias Schwinn, DIA; and Irina Bogdan - STUDIO X, Prof. Christos Passas, DIA. Christos Passas, DIA), Bence Pap (Zaha Hadid Architects, London, UK), Andrei Gheorghe (Professor at the Universität für Angewandte Kunst, Vienna, Austria) and Alexander Kalachev (Assistant at STUDIO X, Dessau Institute of Architecture, Dessau, Germany). This collaboration made it possible to enroll more than 55 participants from both academic and professional backgrounds, who worked for 8 days in various configurations on concepts and study models as well as on the final realized projects. This workshop was supported by Ruukki Romania and realized in collaboration with UAUIM and ASAUIM. MOCKUP VS MODEL In addition to the theoretical part of the workshop, which is necessary for most of the participants of such an event, we aimed to focus on the creation of 1:1 scale prototypes. In this way, the participants are confronted with problems that they have to solve, given the nature of such a workshop, in a short time and in teams. Implicitly this means that they have to consider from the outset both the qualities of the material and the proposed shape, and go through some design optimization steps - whether it is the overall shape or the design of the components used. Such processes are less relevant when making small-scale models. From the very beginning of the workshop, participants worked in groups of five, and on the fourth day of the workshop three of the eleven concepts were chosen to be realized in 1:1 scale. These fell into 3 categories: HEXigloo - pavilion made from components, Wishbone - space installation and VIRULENCE - parasitic/emergent installation. IMPACT What becomes clear from this workshop is the need for similar events given the exponential growth of interest in computational design. In the same vein, it is evident that there needs to be a paradigm shift both academically and professionally. Advanced technologies should no longer be viewed with reluctance and skepticism, but embraced and exploited. |

| REASONING The workshop is a response to the existing demand in terms of computational design, taking into account the academic schedule which does not offer anything alike. We were interested in a collaboration with foreign tutors in order to be able to cope with a big number of participants. Therefore we have invited Bence Pap (Zaha Hadid Architects, London, Great Britain), Andrei Gheorghe (Professor at Universität für Angewandte Kunst, Vienna, Austria) and Alexander Kalachev (Assistant at STUDIO X, DIA, Dessau, Germany) to join us (T_A_I, Tudor Cosmatu - STUDIO X, Prof. Christos Passas, DIA; Andrei Raducanu - Studio Neil Leach and Tobias Schwinn, DIA; and Irina Bogdan - STUDIO X, Prof. Christos Passas, DIA). This collaboration made the participation of over 55 students and architects possible, which during the 8 days have had to work in different configurations on both concepts and study models as well as on the final projects. This workshop has been powered by Ruukki Romania and is a result of a collaboration with UAUIM and ASAUIM. MOCKUP VS MODEL Apart from the theoretical part of the workshop, which was necessary for most of the participants, we have decided to focus our efforts on designing prototypes at a 1:1 scale. This way, the participants are facing specific problems which they have to solve in a short period of time while working in teams. Implicitly this means that from the very beginning they have to take several conditions into account such as material properties, formal/structural properties of the design while always considering possibilities of design optimization - either a general shape optimization or a component based optimization. These kind of processes are less important when dealing with a small scale model, thus the difference between a mockup and a model. From the very first day of the workshop the participants had to work in groups of five people each, so that in the end of the fourth day, three finalist projects could be elected out of the eleven concepts, in order to be built at a 1:1 scale. These projects were defining 3 categories: HEXigloo - component based pavilion, Wishbone - spatial installation and VIRULENCE - parasitic/emergent structure. IMPACT What became clear after this workshop is that similar events need to happen (in Romania), given the exponential increase of interest in the area of computational design. It is also obvious that a paradigm shift has to happen both on a academical level as well as on a professional level. New and advanced technologies should no longer be treated with reluctance and skepticism but should be embraced and exploited. |

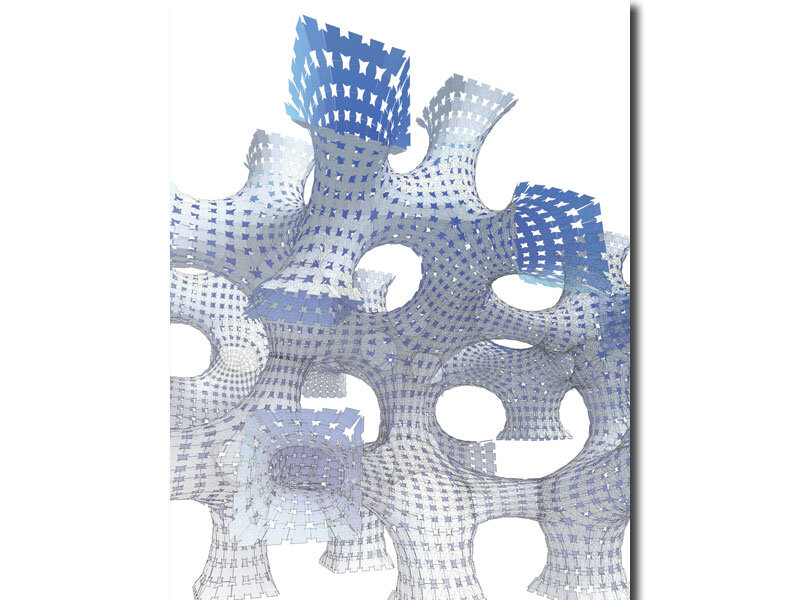

HEXIGLOO:

Echipa/Team Members: Alexandru Dâmboianu | Andreea Nica | Andreea Nica | Andreea Hrișcu | Ana Maria Pop | Ana Maria Pop | Bogdan Samoilă | Bogdan Samoilă | Cristian Bohăniță | Daniel Mitrofan | Irina Șargov | Ina Dumitriu | Mihai Pascalau | Oana Eremia | Sorina Simion | Teodora Răducă

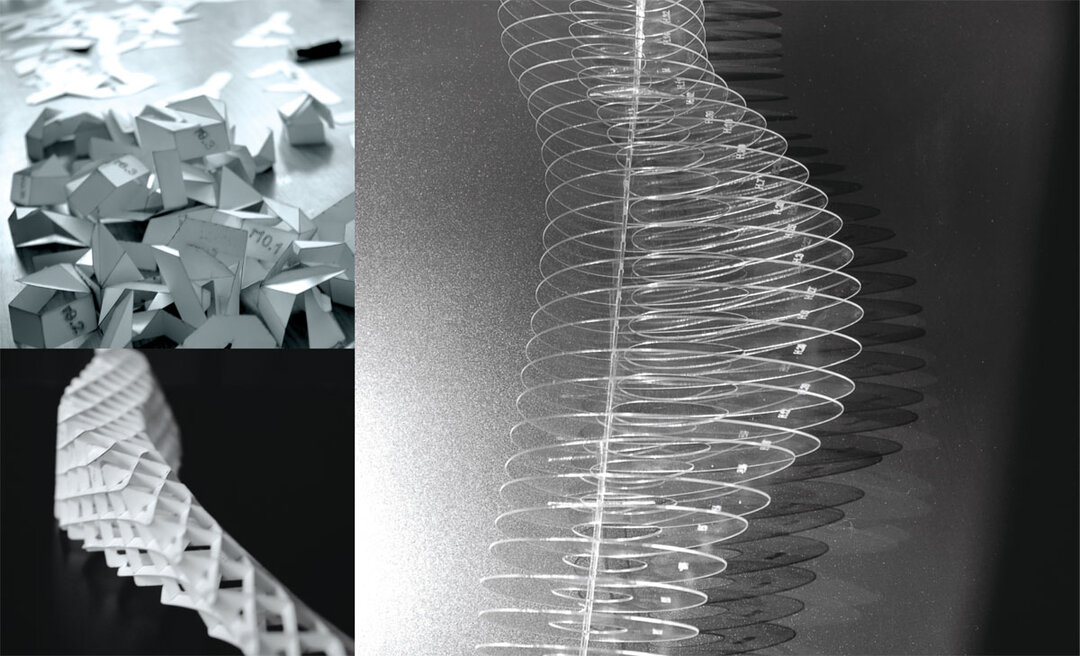

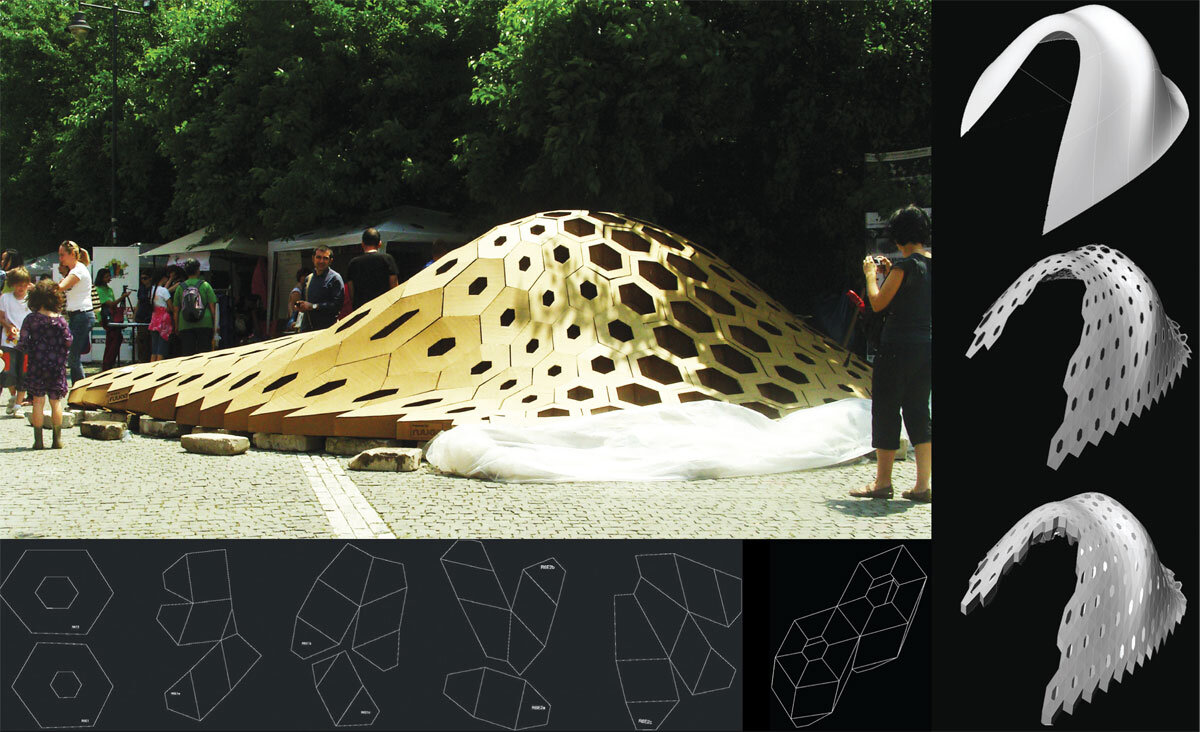

| From the very beginning the concept aroused our interest. What was proposed was a surface imitating the igloo typology, made of hexagonal shaped reactive components that serves as a pavilion. The structure is composed of 14 rows with 14 columns and 196 elements. From the early days, study models were made using thin cardboard sheets to see how the joints between components could be optimized on an architectural scale, as well as how the components could react to an external factor. The first models used the logic of tongue and groove joints, but after initial tests this proved to be incompatible with both the final material and the proposed shape. At the same time it was aimed to optimize the method of realization of the unfolding of the components, in relation to the size of the available cardboard glues and the maximum cutting surface of the laser-cutter (900x600 mm). In the first instance, the unfolding of the elements was realized using a script written in VB.NET, which does this for geometries composed of plane elements. Due to the material used, the best method of fastening was considered to be the one realized with flexible plastic "mouse" type elements allowing minimal local deformations and not damaging the cardboard. By design, it was proposed to extrude the hexagonal base, mapped on the surface, vertically for each individual component, to ensure sufficient clamping surface between the elements, as well as to give rigidity to the overall structure. It took 4 days to finalize the design, cut the parts, assemble them and compose them into their final shape. Within the team, two groups were created: one working on the composition of the elements and the second one working on the realization of sub-assemblies of parts to prepare the final assembly. |

| This concept sparked our interest from the very beginning. The proposed surface resembles an igloo and the pavilion structure is based on reactive hexagonal components. The structure is composed of 14 rows and 14 columns consisting of 196 elements. Thin cardboard study models have been used from the very beginning in order to check and optimize the connections between components at an architectural scale and also in order to figure out how the components can react to an exterior factor. The first tryouts were using a plug-in connection type, which after a few tests proved to be incompatible with both the final material and the overall proposed shape. In the same time the optimization of the unrolled components in terms of lay outing and fitting them on the maximum sheet size for the laser cutter (900x600) had to be taken care of. At first a VB.Net script has been used in order to unroll the components made out of flat sheets. Because of the given material, the best connection type has been considered to be a flexible one, allowing local, small deformations to happen while maintaining the integrity of the material thus not allowing the material to rip apart. In order to ensure the rigidity of the structure, the mapped hexagonal geometries have been extruded vertically for a given height. The time needed to complete the design-, cutting-, component assembly and structure assembly phase has been that of 4 long days. Within the team there have been two active groups working in the same time: one which was dealing with assembling the cut unrolled elements and another one which was creating bigger subsets in order to prepare for the final assembly. |

WISHBONE:

Echipa/Team Members: Adriana Mihăilescu | Ina Leonte | Ina Leonte | Maria Anna Kowalska | Mircea Mihai | Mircea Mihai | Ana-Maria Anton | Vlad Vernica | Vlad Vernica | Cristina Popa | Veronica Popescu | Oana Eremia | Raluca Boca | Cristina Enache | Ina Dimitriu | Alina Medrihan

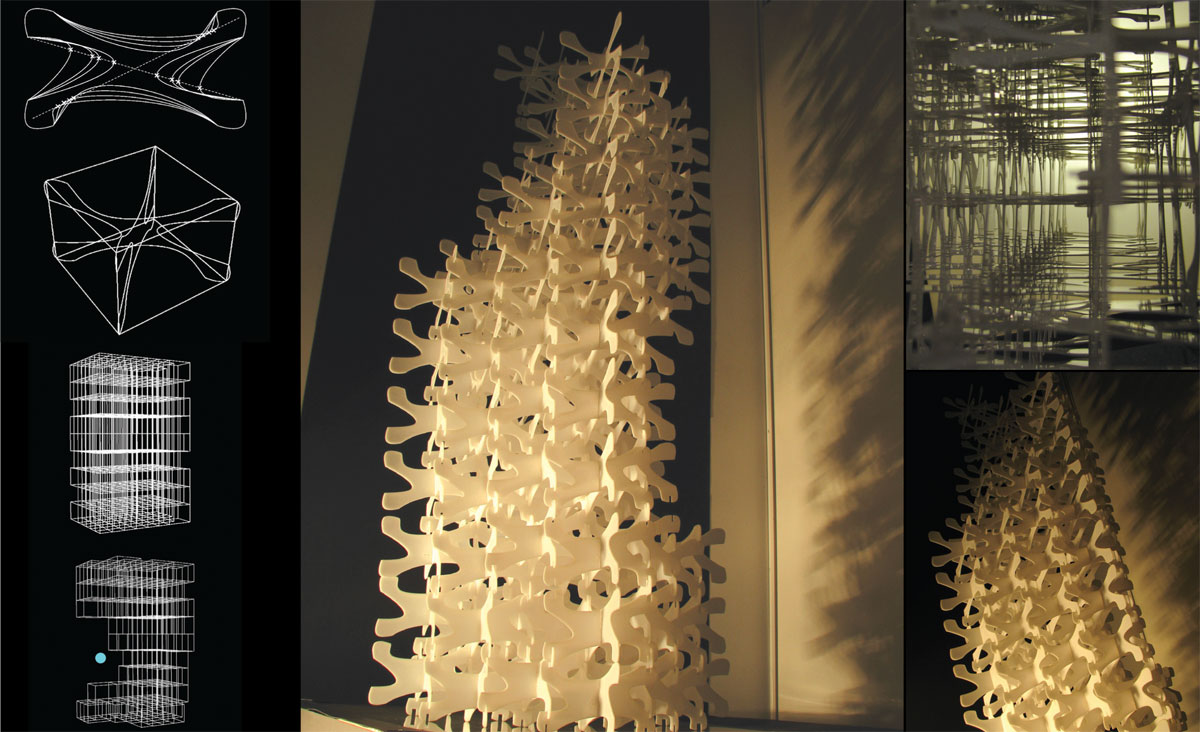

| This installation represents a volume defined by a series of elements arranged in a regular grid, whose suppleness is directly proportional to the height at which the component is located in the structure. The basic idea of this concept is to create an architectural installation which, by superimposing the constituent elements in perspective, creates a three-dimensional visual filter, reminiscent of the moiré effect. The juxtaposition of the constituent elements gives rise to 'visual tunnels' that can emphasize certain directions of vision. The installation consists of 219 elements made up of two similar planar faces. Various layout studies were carried out to find a way of joining the pieces together in a way that would ensure structural integrity as well as being visually unobtrusive. The solution opted for was to use round, chertized planar elements for the joint. Given that the number of components that meet in a clamping element is not constant, we had to use 6 different, parametrically controlled, sizes of the laps. The assembly of the installation took 10 hours and approximately 300 linear meters of 6 mm corrugated board were cut. |

| This installation represents a volume defined by a series of elements which sit in a regular grid, and whose slenderness is directly proportional to their position height-wise. The main idea of this concept is to create an architectural installation which through the overlaying view of elements in perspective creates a three-dimensional visual filter that alludes to the moiré effect. The juxtaposition of the elements generates "visual tunnels" that can be used to accentuate certain viewing directions. The installation is composed of 219 components that are made of 2 planar elements. There have been several study models made, both with and without additional connecting elements, in order to find a version that both assures rigidity and is esthetically acceptable. We ended up using round-shaped planar connectors, that were provided with slots. Since the number of elements that converge towards a connector is not constant, 6 types of joining elements needed to be designed. The pieces were laser-cut (300 linear meters) out of 6 mm corrugated fiberboard and the assembly took about 10 hours. |

VIRULENCE:

Echipa/Team Members: Iulian Canov | Vlad Stoica | Alexandru Robert Tudose | Cristina Zlota | Anamaria Arnăutu | Magdalena Goga | Miroslav Orloev | Mădălin Gheorghe

| The basic idea of the algorithm is to produce a complex system of repetitive elements with a regular geometry, which can parasitize a given space, similar to the way a pathogen multiplies in an organism. At the geometrical level, the idea of using three repetitive elements of different sizes on emergent curvilinear paths, i.e. spontaneous and unpredictable paths, was chosen in the first instance. In the case of the UAUIM installation, the handrail of the spiral staircase in the main hall was chosen as the space for the installation. The elements were designed to overlap each other substantially to allow the connections to use two joining elements each that provide good rigidity. With a fairly high degree of repeatability, both geometrically and in terms of connections, the assembly time was considerably shorter than other projects. Approximately 900 linear meters of 6 mm cardboard were cut for this structure. |

| The main idea of this algorithm is to produce a complex system of repetitive regular elements, that would take over a space in a parasitical fashion, similar to a pathogen that spreads in an organism. Three types of elements were used, that had a similar geometry but different sizes. These elements were used in an algorithm that combined them in such a way that they formed curbilinear emergent paths. In the case of the UAUIM exhibition, the handrail of the staircase in the main hall was used as "host" for the emergent structure. The elements were designed to overlap significantly so that the overall structure gaines stability, through the usage of 2 spread spread apart connectors at each joint end. The components being repetitive in this case, made the assembly time significantly shorter than in the case of the other two models. Approximately 900 linear meters have been cut out of corrugated fiberboard for this project. |