Materials and materialisation at the Free Time Factory – Turda. Wooden structures Workshop (2014)

Brewery

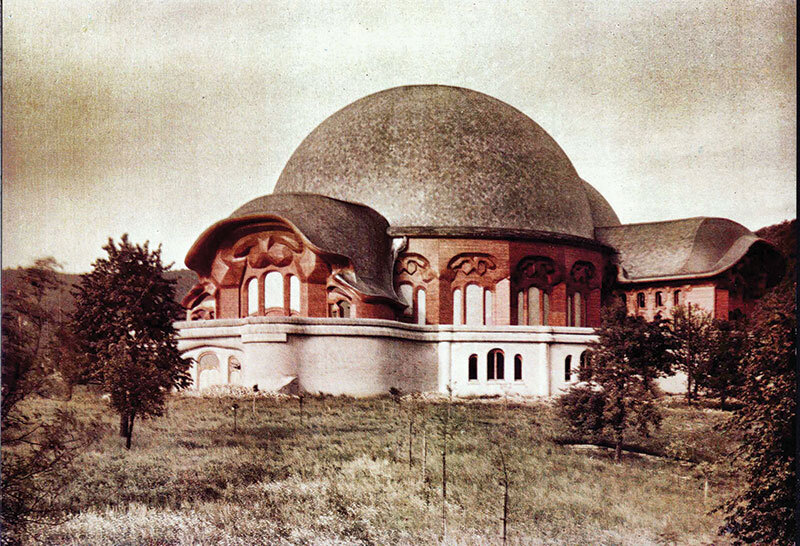

The former Brewery of Turda is located on the banks of the Arieș River, at the intersection of the main access roads into the city, between the old part of the city and the industrial area. Built between 1796-1814, the building served as a production base for three beer brands: Mendel, Turdeana and Ursus. Today, the complex is classified as a historical monument and the building is undergoing a regeneration process initiated by the Rațiu family. A first step has been achieved by setting up the "Fabric of Free Time" in one of the former brewery premises - a community center for young people, where volunteering, community involvement and personal development are promoted.

Vision and project

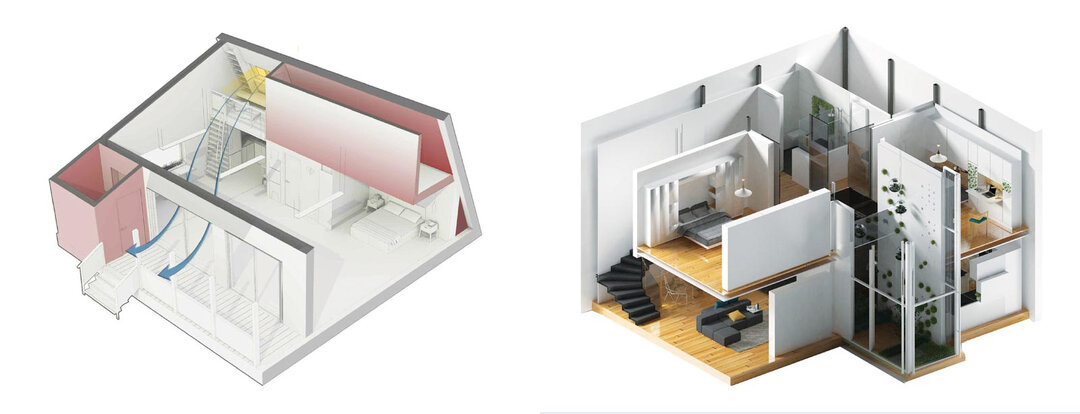

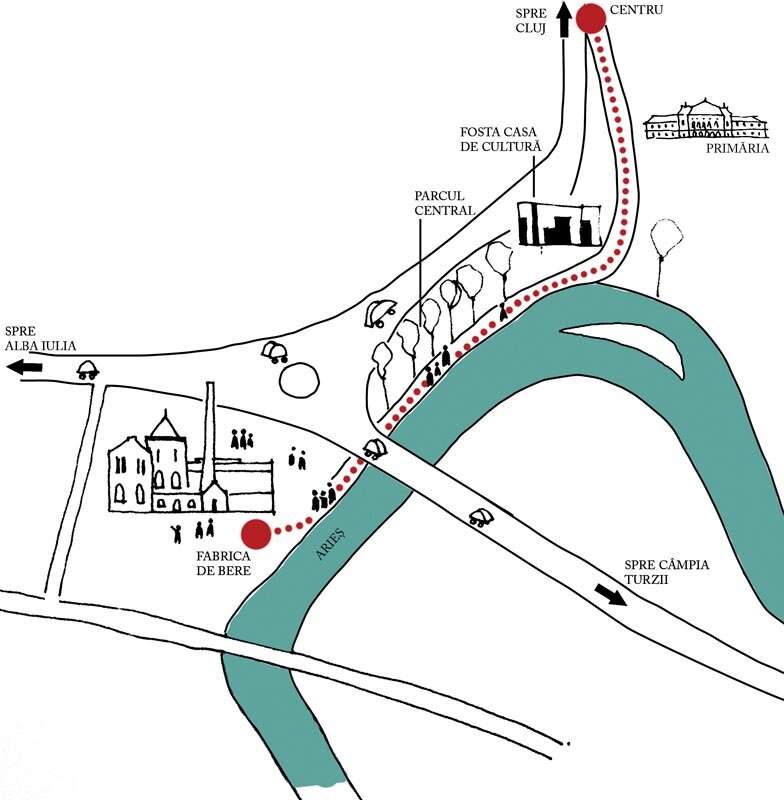

In order to revitalize the ensemble and reintegrate it into the local community, a study was conducted on the relationship between the Brewery, the Arieș River, the Central Park and the centre of Turda. Thus, a strategy was established to connect the brewery directly to the river and to create a promenade along the Arieș River, linking the brewery to the park and further to the city center.

In order to create a landmark of the "Leisure Time Factory" on the promenade along the Arieș River, it was proposed to organize a workshop in which a covered stage with a wooden structure would be realized. It was located near the river and is used for the outdoor activities of the "Fabricii de Timp Liber" and the "Ion Rațiu" Theater Workshop. The creation of this landmark is a first step for the proximity to the river, foreseen in the strategy to connect the factory with the Arieș river and the center of Turda. The decision on the final position was marked by the footprint of a former warehouse, today demolished, with plan dimensions of 6x14 m, taken over by the new built object.

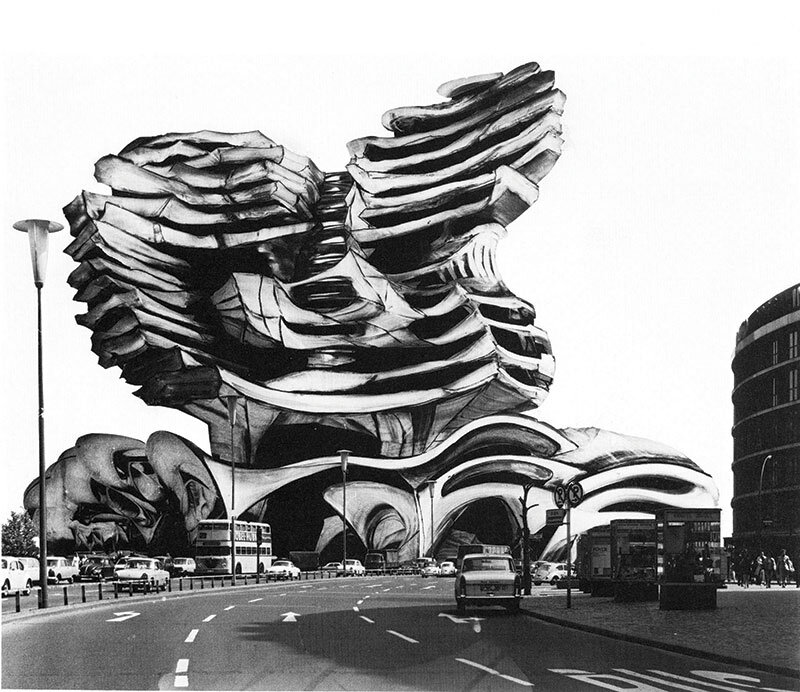

Among the objectives of the project were: to complete the facilities of the "Leisure Time Factory" in the courtyard of the former brewery and to reactivate the brewery premises and its courtyard for the benefit of the community. To this end, the Factory was transformed into a multi-purpose complex, where different cultural activities can be held (end-of-year performances of the city's schools and kindergartens, open-air concerts, various other events that need exhibition space) - the city of Turda lacks a multi-purpose hall or a cultural center. The aim was to offer the possibility of staging outdoor plays for the "Ion Rațiu'' Theater Workshop, to orient the activities operating within the brewery towards the river and to create a visual connection with it. Last but not least, it was important to keep the proposed activities within a minimum budget, to use local materials and to involve the community together with specialists from various fields, as the workshop also has a didactic purpose.

Strength structure and materials used

The design of the stage was realized taking into account the objectives of the project and the material resources we had at our disposal: the financial resources of the Rațiu Foundation and the wood material received as sponsorship from some partners. Thus, we started the project knowing that we could use the fir wood and beech plywood that we had at our disposal.

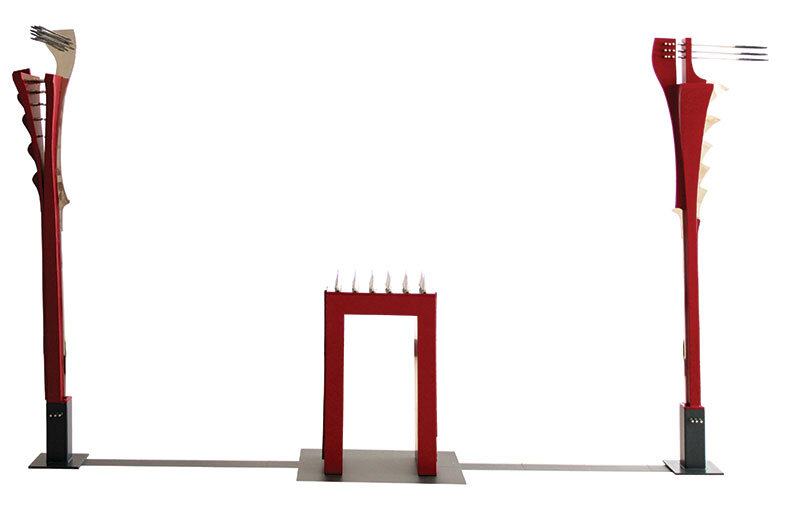

This resulted in the shaping of the resistance structure for the stage roofing, which, for the 14 m opening and the height of 7 m, was generated as the optimal shape in terms of material consumption and the way such a structure behaves to external loads (snow and wind).

The way in which the assembly responds to the demands of the external forces provides an intuitive and natural way to shape the structure in terms of stress distribution. This efficient distribution analysis helps to choose the material within the assembly and how it should be configured to work optimally with minimal material consumption. The result is a portal frame with columns hinged at the base and beams rigidly connected to the columns.

For maximum structural efficiency, the columns and beams were realized as cheson profiles (rectangular pipe profiles), with wooden flanges 2x45x105 mm and two lateral beech plywood hearts of 20 mm. All elements (columns and beams) have a variable cross-section, following the shape of the stress diagram in the structure.

Both the wooden footings and the plywood hearts were fastened together with wood glue and self-drilling stainless steel wood screws. Why did we use this system? Beech plywood is at least four times stronger than the wood commonly used as building material (fir, spruce), for twice the weight. It behaves much better under stress in both directions and is more resistant over time. In the cantilever, the wooden soles take most of the load, and the beech hearts contribute significantly to the stability of the assembly and prevent buckling of the posts.

In this system, the final consumption of material for the stage structure was very low compared to the realization of the structure in a classical system. This was possible because the design took into account the adjustment of the shape of the architectural object, depending on the reaction of the structure to external forces and the way the materials used (wood and plywood) react to the forces and over time.

Stage execution

The stage was realized entirely with local volunteers and students from the architecture faculties of Bucharest, Cluj and Iași in 14 days. Two professional carpenters were involved for two days. The workspace was organized as a practical workshop, where woodworking techniques were taught: from the basics (measuring, tracing and cutting materials) to the use of sophisticated equipment and machinery. All pieces were made in prefabricated system, on workbenches, on which templates were made. Assembling the prefabricated parts took two days (using scaffolding and a small crane) and three days to finish the assembly.

At the end of the workshop, participants learned about how wood can be used intelligently as a building material, depending on its species and properties, about specific joints and how to use connectors correctly. At the same time, the city of Turda, through the Rațiu Foundation, benefits from this workshop with a new performance space.

Organization

Rațiu Center for Democracy (CRD)

Pamela Rațiu - executive director

Doinița Pop - project coordinator

Free Time Factory

Youth Center inside the Brewery

Pro Patrimonio Foundation: arh. Șerban Sturdza, arh. Oana Androi, arh. Ruxandra Sacaliș, eng. Marius Șoflete.

Design

Architecture

S.C. Prodid S.R.L.: arh. Oana Androi, arh. Ruxandra Sacaliș, consultant arh. Șerban Sturdza.

Structure

"Inginerie Creativă" - eng. Marius Șoflete.

site

Site manager and technical responsible for execution: eng. Tichy Ana

Workshop coordinator and responsible for the participants' training on carpentry and wood engineering: eng. Marius Șoflete.

10 workshop participants - architects and landscape architects from Romania and France: Thomas Bleton - landscape architect, Viorela Bogatu - student-architect, George Dinu - architect, Miléna Gross - landscape architect, Andreea Machidon - architect, Nicolas Masurel - landscape architect, Karina Picuș - student-architect, Alexandra Rîmbu - student-architect, Mihai Timcea - student-architect, arh. Oana Androi, arh. Ruxandra Sacaliș, eng. Marius Șoflete

CRD volunteers

Utility climber: Andrei Ilieș

Photo credit: Oana Androi and Ruxandra Sacaliș