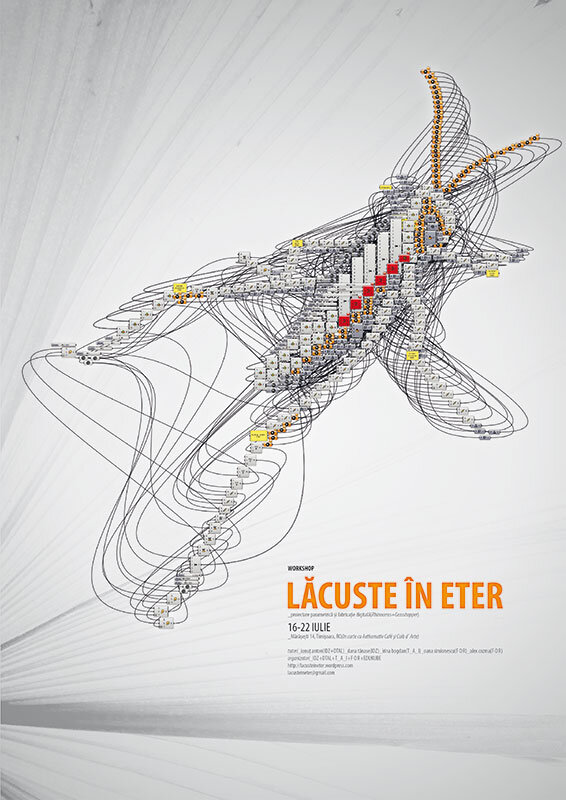

Locusts in the Ether. Parametric design and digital manufacturing workshop in Timisoara July 16-22, 2012

TUTORS:Ionuț Anton (IDZ), Dana Tănase (IDZ), Irina Bogdan (T_A_I), Alex Cozma (F O R)

Organizers:EDUKUBE (Zoran Popopovici and Adriana Hanțiu), F O R (Oana Simionescu and Alex Cozma) + T_A_I (Irina Bogdan), IDZ (Ionuț Anton and Dana Tănase)

With the participation of:Paul Popescu (Modulab)

Participants: Irina Acasandre, Roxana Boloș, Agnes Brull, Simona Cojocaru, Dragoș Cristian, Simina Dimcea, Simona Farcaș, Anda Gheorghe, Smaranda Ghiniță, Vlad Igăntescu, Ioana Iordan, Laura Iosub, Anda Jugănaru, Roxana Mirea, Călin Negret, Roxana Pau, Andrei Pădure, Boris Peianov, Diana Poiana, Iulian Popa, Ștefan Prigoreanu, Luiza Rădulescu, Laurențiu Stoian, Egyed Szabolcs, Ioan Emilian Veliciu

Main sponsor: MONS MEDIUS

Sponsors:OAR Timiș, Clearsign / Amulette, Atelier Print, Hostel Costel

Photo and art credit:Laurențiu Stoian, Alex Cozma, Oana Simionescu, Ionuț Anton, Zoran Popovici

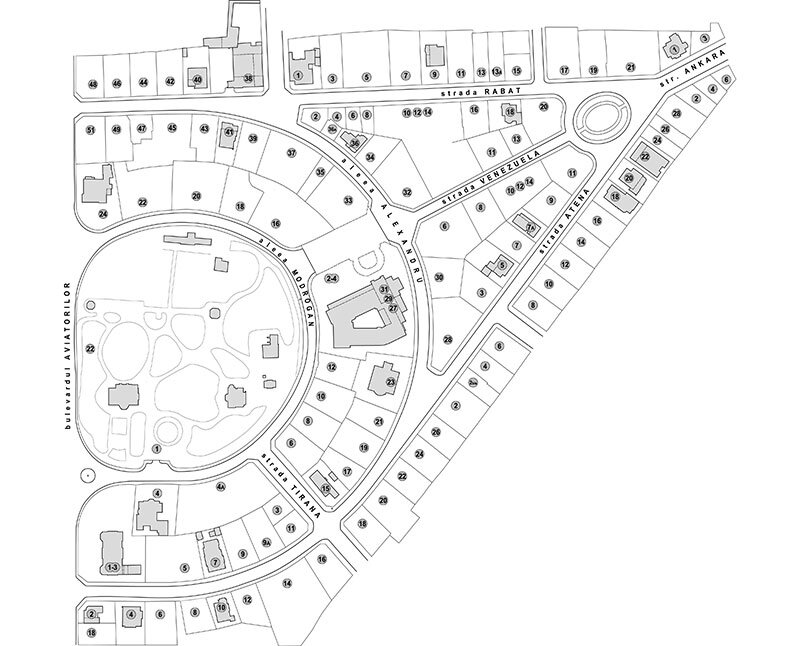

During the seven-day intensive workshop, participants learned to use digital technologies to generate answers in relation to a given context. They used data extracted from the site as parameters within the creative process of the architectural object. Thus, the relationship between the space of the enclosure at 14 Mărășești Street in Timișoara and a parametrically developed architectural object was pursued. The challenge of testing digital technologies was combined with that of sustaining and revitalizing the community coagulated in the center of one of the precincts of the Cetate district - organic spaces whose effervescence has disappeared in recent years.

The legitimacy of using tools specific to the digital environment is given by their integrative capacity, by their ability to generate multiple options and, above all, to relate all these parameters and translate them into a real object.

Using digital fabrication technologies, computationally generated virtual objects were first materialized on a small scale and finally produced on a 1:1 scale. Using these technologies, participants integrated feedback loops into the design process, which involve physically realizing prototypes, testing them and reintegrating the result as parameters into the design.

The workshop was divided into three stages, with the first stage taking the form of a series of lectures designed to introduce the topics of parametric design and digital fabrication, as well as an introduction to the use of Grasshopper parametric design software and its tools for energy analysis (Geco + Ecotect) and physical force simulation (Kangaroo). In the next stage of the workshop, participants explored the relationships between site geometric parameters and a process design using natural force simulation. The five working teams each proposed a plant-response to the theme.

The last part of the workshop was dedicated to the materialization, using digital fabrication methods, of the prototypes proposed by the working groups, as well as the realization of two of the five projects at 1:1 scale.

The results of the workshop are, in fact, the material traces of a complete working process, starting from the physical parameters transposed into the digital environment.

These are computationally processed to generate a virtual object, which is then rematerialized through digital fabrication techniques. Throughout the workshop, participants had hands-on experiences with numerous cutting-edge technologies, using an open source 3D scanner (Kinect), open source ABS 3D printer (RepMan), as well as CNC cutting tools (CNC Router and laser).

In a relatively short time, 3D printed mock-ups of the designs, multiple prototype versions of full-scale components for concept testing and two final 1:1 scale installations were realized.